The perfect solution for our customer

A perfect production environment is an important requirement for economically manufacturing pharmaceutical and healthcare products which includes the protection of operators and materials. PTA’s cleanroom technology offers you a wide range of solutions in dealing with active pharmaceutical substances.

The Laminar Flow technology from PTA delivers ideal conditions for your production environment.

Our Laminar Flow Systems are exclusively developed and made-to-measure for individual customized requirements. All systems correspond to the general requirements of the pharmaceutical industry, current standards as well as GMP and FDA standards.

PTA Laminar Flow systems correspond to the clean room class acc. to ISO14644.

PTA Cleanroom Technology: For best possible process safety

Laminar-Flow

Vertical and horizontal laminar flow

Protection

… of the surrounding area due to a circulating system

Material

Stainless steel 1.4301 (AISI 304) design or higher grade

Filtration

Multistage filtration with final HEPA filter filtration

Protection

… of raw materials or substances due to contamination

Safety

… for operators due to contamination

Standards

Clean room acc. ISO14644 / Safety class 1 to 3 acc. DIN 12469

GMP / FDA

design acc. GMP / FDA standards

Download Flyer - Laminar Flow

PTA Laminar Flow – for product and operator safety

Work space

- Weighing booth for sampling

- Touchpanel

- Flush LED-lights

- 3-way filtration

- Special vacuum for barrels

- Partition wall made of glass/stainless steel

- Partition wall with integrated collision protection

- Manuel sluice gate in partition wall

Working bench

- 3 working areas

- Continuous working table

- 3-piece glass

- Touchpanel

- Flush LED-lights

- 2-way filtration

- Separate guiding for exhaust air

Compact working bench

- Open design

- Touchpanel

- LED-lights

- 2-way filtration

- Lift table

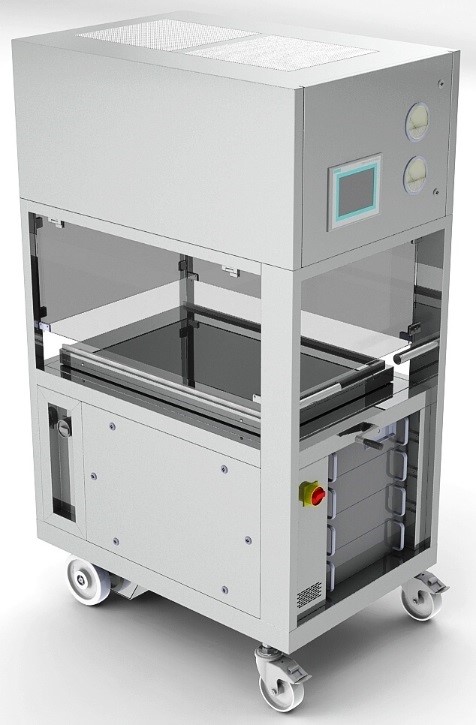

LF-Trolley

- Extendable table

- Touchpanel

- 2-way filtration